| |

|

Data center cooling |

|

| |

| |

| Energy Integrations for Data Centers |

-

Based on the framework of “Energy Saving, Energy

Utilization, and Energy Generation”, Kaori is

proposing the energy integration solution, or

the“Energy Trio”. With the cloud data center as the

main axis, the company proposes a liquid cooling

solution for server cooling, and in the backup power

support, the hydrogen technology is combined with a

5kW methanol fuel cell, and combined with a

high-force plate heat exchanger. Waste heat recovery

management can increase the overall energy

efficiency by more than 40%, and fully demonstrates

innovative thinking and complete technical

capabilities in the energy field.

|

|

|

| |

| Energy Trio |

- Energy Generation - Fuel Cell Generators

- Energy Preservation - Liquid Cooling System for

Servers

- Energy Recovery - Heat Exchanger/Heat Pump

|

| |

| ◎ Energy Trio - 1 |

| ◆ Energy

Generation - Fuel Cell Power System |

-

Kaori hydrogen fuel cell power generator

is safe, high efficiency, clean and

green energy, and can operate stably for

a long time. It can be used as auxiliary

power, emergency backup power,

independent power supply, and integrated

power generation. Replacing the dilemma

of traditional highly-polluted diesel

power generators and a large number of

hydrogen cylinders, using

low-environment hazard, high energy

density, convenient storage and

transportation, safe methanol water,

natural gas, real estate hydrogen,

immediate consumption, combined with

self-made remote monitoring system, let

green electricity go everywhere .

|

|

|

|

|

●

Hydrogen

Generator |

|

Hydrogen production

rate |

75 ~ 85 LPM |

|

Hydrogen purity |

> 99.999 % |

|

Purifier |

PSA or Pd type |

|

Fuel consumption |

110 ml/min |

|

Fuel type |

59 ~ 62.5 wt% methanol

/ DI water |

|

Noise |

≦ 45db (@ 1.5m) |

|

Weight |

90 kg |

|

Dimension (W x D x H) |

585mm x 680mm x 430mm |

|

|

●

Fuel

Cell Power System |

|

Rated power |

5 kW |

|

Voltage ouput |

48 ~ 55 VDC |

|

Ambient temperature |

5℃ ~ 40℃ |

|

Fuel consumption |

80 ~ 102 ml/min |

|

Fuel type |

Methanol water or

natural gas |

|

Noise |

≦ 65db (@ 1.5m) |

|

Weight |

380 kg |

|

Dimension (W x D x H) |

800mm x 1000mm x

1760mm |

|

| |

| ◎ Energy Trio - 2 |

| ◆ Energy

Preservation – Liquid Cooling System |

-

With the continuous improvement of the

world's awareness of energy conservation

and carbon reduction, how to effectively

reduce the energy consumption of data

centers has become a major concern in

the telecommunications industry. All

e-commerce giants face more serious

cooling issues in their self-built data

centers. Kaori’s immersion cooling

system is rigorously verified by cloud

servers, generating huge amounts of heat

during fast and large data volumes.

Kaori’s high cooling capacity immersion

coolant distribution unit(CDU) plays an

important role.

|

|

|

|

|

cooling capacity |

30 ~ 100 kW |

|

Primary Coolant Fluid |

Water / anti-freezer |

|

Primary Fluid Temperature Range (℃) |

30 ~ 35 |

|

Secondary Coolant Fluid |

di-electric fluid |

|

Secondary Loop Flow Rate (LPM) |

150 ~ 750 |

|

Secondary Fluid Temperature Range

(℃) |

40 ~ 45 |

|

Dimensions (meter) |

H1.5 x L0.8 x 0.6

H1.5 x L0.8 x 0.8 |

|

| |

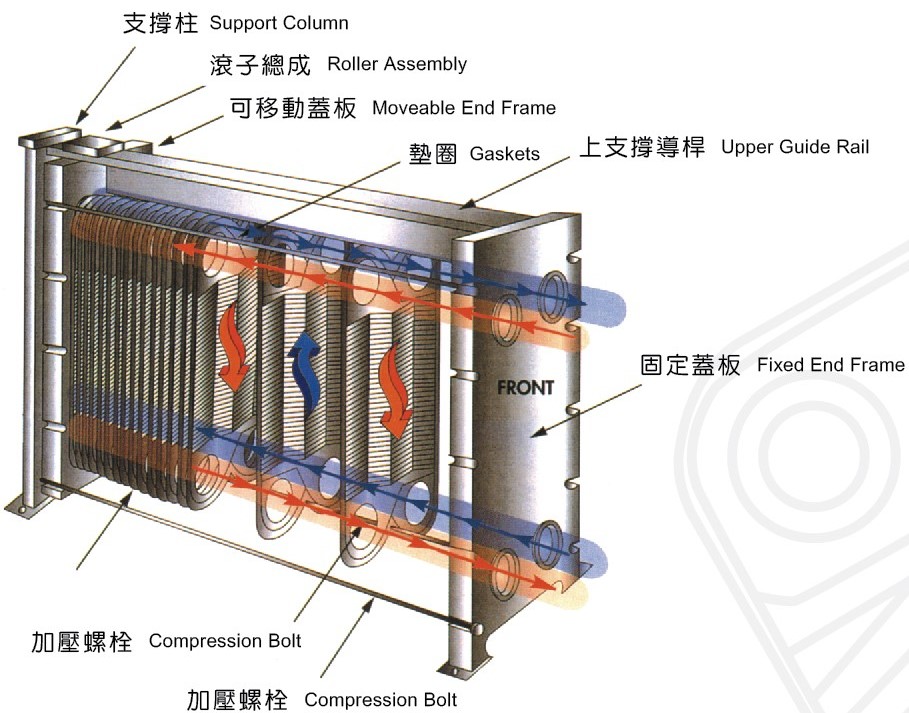

| ◎ Energy Trio - 3 |

| ◆ Energy

Utilization - Heat Recovery |

-

Variety

of Plate Selections Variety

of Plate Selections

The heat exchanger's connection diameter

ranging from 3/4" to 20“(max.), offering

a wide range of selections.

-

Gasket Plate

Heat Exchanger of Designated Materials

Designated Materials such as titanium

(Ti), SMO254, aluminum alloy (C276),

high nickel alloy, etc., suitable for

corrosive fluids such as seawater,

salted water, salinated, electroplating

solution sulfuric acid, hydrochloric

acid and other acid-base fluids.

-

Semi-welded

Plate Heat Exchanger

Laser-welded plates are available in

temp. from -40 to 170 ° C and pressures

up to 25 bar for highly unstable fluids

(hazardous fluids) and cryogenic

refrigeration applications.

-

High

Efficiency, Energy Saving and

Environmental Friendly

The special pattern design can cause

high turbulence even at low flow rates,

achieving high heat transfer efficiency,

saving energy, reusable , and durable

for at least 10 years.

|

|

| |

| ◆ Heat recovery

application (35℃ ~

45℃ Hot water) |

○ District heating supply

○ Supply livelihood,

industrial hot water

○ Melting snow in buildings

in the cold zone |

| |

| |

| |

| TOP |