| ¡@ |

|

Gasket Plate Heat Exchanger |

|

| ¡@ |

| ¡@ |

| Laser Semi-Welded Module |

| Background |

In the past no satisfying solution was offered using gasketed plate heat

exchangers for special process conditions or aggressive media.

The

limitation was always the gasket material. For this reason, the

complete

ThermoLine-plate heat exchanger program was also made

available in

a laser welded configuration. Thus, a new field of

application was

opened

for special process conditions, also taking into

account

environmental

and safety requirements. |

|

| ¡@ |

| Advantages |

- Compact design, low weight.

- Quick and low cost installation.

- Excellent heat transfer coefficient.

- Minimm risk of leakages.

- Gasketed heat transfer surface easy

to clean.

|

- High flexbility.

- Low hold-up volume.

- High corrosion resistance.

- Flexible capacity extension.

|

|

| ¡@ |

| ¡@ |

| Working Principle |

| Two heat exchanger plates are welded together to a gas-tight module by means of laser technology .By doing so, a

flow channel for the aggressive (or the gasket attacking media) is built, which is hermetically closed to the outside.

Only two ring gaskets, made of high resistant material located in the port holes between two welded modules, are in

contact with the aggressive media.

The other flow channel for the non-aggressive media is sealed by various elastomer gaskets, depending on the

individual application. The gaskets are normally fixed without the need for glue but are also available in the glued-on

¡@ version. The leakage between the two media is prevented by a double weld, and a double ring gasket in the port

holes. If a leakage occurs for any reason, the leak will be external and easily detected.

In spite of the use of welded modules, the proven flexibility of plats heat exchangers is maintained. By adding or

changing modules, the heat exchanger capacity can be adjusted to the individual requirements.

The laser welded modules can be used for temperatures from -40oC + 170oC, and for pressures up to 25 bar. |

| ¡@ |

| ¡@ |

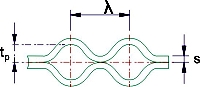

| Plate Structures |

| PLATE TYPE |

CORRUGATION DEPTH tp (mm)

PLATE THICKNESS S (mm) |

CORRUGATION ANGLE A |

|

|

|

|

| Power Line PL |

2...2.5 |

0.5...0.8 |

30¢X |

- |

| Standard Line SL |

3.5...4 |

0.5...0.8 |

30¢X |

60¢X |

|

| ¡@ |

| ¡@ |

| Laser Semi-Welded Plate Types |

| ¡@ |

|

|

|

|

|

|

|

Plate type TL

|

90 |

150 |

400 |

250 |

500 |

650 |

850 |

Port hole (DN)

|

40 |

40 |

80 |

100 |

100 |

200 |

200 |

Length (mm)

|

721 |

981 |

1383 |

1014 |

1495 |

1495 |

2034 |

Width (mm)

|

244 |

244 |

369 |

437 |

437 |

586 |

586 |

| Length / Width |

2.95 |

4.02 |

3.75 |

2.32 |

3.42 |

2.55 |

3.47 |

|

| ¡@ |

| ¡@ |

Laser Semi-Welded in R22 / R134a

Refrigeration Application |

| R22 / R134a |

TEMPERATURE RANGE |

GASKET

MATERIAL |

| Evaporator |

-30¢XC to -20¢XC

> -20¢XC |

|

| Condenser |

< 130¢XC |

CR-HT |

| Desuperheater |

< 130¢XC |

CR-HT |

|

Laser Semi-Welded in NH3 Refrigeration

Application |

| Ammonia |

TEMPERATURE RANGE |

GASKET MATERIAL |

| Evaporator |

-40¢XC to -20¢XC

> -20¢XC |

| NBR-LT / CR-LT |

| CR-NT / CR-HT |

|

| Condenser |

< 130¢XC

130¢XC to 150¢XC |

CR-HT

HNBR |

| Desuperheater |

< 130¢XC

130¢XC to 150¢XC |

CR-HT

HNBR |

| Oil Cooler |

< 110¢XC

110¢XC to 150¢XC |

NBR

HNBR |

|

|

| ¡@ |

| ¡@ |

| Laser Semi-Welded Plate Material |

| STANDARD MATERIALS |

THICKNESS |

1.4301( AISI304 )

1.4404( AISI316L )

1.4571( AISI316Ti ) |

0.5mm¡ã0.8mm |

|

| Laser Semi-Welded Plate Material |

| SPECIAL MATERIALS |

THICKNESS |

1.4529

1.4539(UNS N08904)

1.4541(AISI 321)

1.4547(SMO 254)

2.4068 Alloy 201

2.4602 Hastelloy C-22

2.4610 Hastelloy C-4

2.4819 Hastelloy C-276

2.4858 Alloy 825

3.7025 Titanium Gr.1 |

|

0.6mm ¡ã 0.8mm |

|

|

| ¡@ |

| TOP |