|

|

|

|

|

|

|

|

| ¡@ |

|

Gasket Plate Heat Exchanger |

|

| ¡@ |

| ¡@ |

| Why use a plate heat exchanger? |

The advantages of the plate heat exchanger begin with its design.

Plate heat exchangers, or PHEs, deliver greater efficiency, lower

cost, easier cleaning and maintenance, and closer approach

temperatures than any other heat transfer technology.

Compared to spiral and shell and tube heat exchangers, PHEs

of similar capacity also take up little floor space and are easy to

expand. The vertical swing out plates allow one to pack thousands

of square feet of heat transfer area into a small space, while still

allowing room for future growth. |

|

| ¡@ |

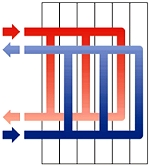

| Flow arrangements |

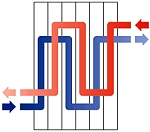

While hot and cold fluids flow in opposite directions across a

¡@

single plate, the flow pattern between plates can be varied.

Plate

heat exchanger flow patterns can be single or multi pass.

¡@

A single-pass arranqement means each fluid flows in the

¡@

same respective direction across all the plates in the unit.

¡@

A multi - pass arrangement is designed in such a way that fluids can change their respective flow directions.

Single-pass units are suitable for most applications, but very low flow rates or extremely close-approach

temperatures may call for the multi pass configuration. |

| ¡@ |

|

|

Single-pass arrangement Suitable

for most application. |

Multi-pass arrangement for application with low

flow rates or close-approach temperatures. |

|

| ¡@ |

| ¡@ |

| Applications |

AUTOMOTIVE

Phosphate tank heaters, seal water coolers, plating

solution cooling, paint heating, welder water cooling,

induction heater cooling, hydraulic oil coolers,

quench

oil

heat exchangers, and cooling tower

isolation. |

¡@ |

¡@ |

TEXTILE

Heat recovery, caustic solution heating and cooling,

ashers, and dye concentrate heating. |

| ¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

¡@ |

¡@ |

¡@ |

BREWING

Brine cooling, water heating, and wart cooling. Caustic

soda coolers, acid coolers, hydrogen gas coolers, and

brine heaters and coolers. |

¡@ |

¡@ |

STEEL

Scrubber coolers, jacket water coolers, slab induction

heating coolers, hydraulic oil cooling, mold water cooling,

refractory liner cooling, roll oil cooling, and cooling of

continuous casting installations. |

¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

¡@ |

¡@ |

¡@ |

CHEMICAL

Process interchangers, brine heating and cooling,salt

refining, process water isolation vapor condensers,

acid heating and cooling, and gasscrubber heaters

and coolers. |

¡@ |

¡@ |

HVAC

Cooling tower isolation, free cooling, heat pump

systems, thermal storage systems, condenser water

heat recovery, district heating and cooling, seawater

isolation,geothermal heating, engine cooling, lube oil

cooling, fuel oil heating, generator cooling, and heating

water with steam. |

| ¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

¡@ |

¡@ |

¡@ |

FOOD

Sugar refining, fructose solution heating and cooling,

whiskey recuperators, yeast coolers, starch coolers and

heaters, corn syrup cooling, and edible oil heaters and

coolers. |

¡@ |

¡@ |

PULP AND PAPER

Digester heaters, blow-down liquor coolers, caustic

soda coolers, boiler blow-down heat recovery,

whitewater, and black liquor heating. |

| ¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

¡@ |

¡@ |

¡@ |

MARINE

Seawater isolation/exchanger. |

¡@ |

¡@ |

METAL WORKING

Quench oil coolers, plating heaters and coolers,

anodizer heaters and coolers, strike solution cooling,

and pickling tank heating. |

| ¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

¡@ |

¡@ |

¡@ |

PETROLEUM

Oil refining, natural gas processing, offshore drilling, and

petrochemical processing. |

¡@ |

¡@ |

POWER

Auxiliary cooling circuit isolation, condenser water

isolation, cogeneration applications, geothermal

applications, refuse burning applications, lubrication oil

cooling, and diesel engine cooling and heat recovery. |

| ¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

¡@ |

¡@ |

¡@ |

Our customers and actual business achievement

Taiwan (Nuclear) Power Plant, Taiwan Sugar Corp., Taiwan Tobacco and Liquor Corp., China Steel Corp., China Ship- building Corp., China Petroleum Corp., Chuanen Company, TamSui Mackay Memorial Hospital, XinDian Tzu Chi Hospital, Veteran General Hospital and Biological Technology Center, National Taiwan University Hospital, NanKang Station of Three Railways, Chunghua Show Chuwan Memorial Hospital, TaiNan Historical Museum, Social Science Building of Academia Sinica, Formosa Plastics Enterprise, Allied Material Technology Corp., Kinsus Interconnect Technology Corp., Toppan Chunghwa Electronics, # 12 Factory of TSMC, # 7 Factory of UMC, Honhai Enterprise, ASE ZhongLi Factory, HannStar YangMei Factory, ProMOS Technologies at Central Industrial Park, Takahashi Inc. at Central Industrial Park, Mosel Vitelic Inc. at Southern Industrial Park, Chimei Inc. at Southern Industrial Park, Texas Instrument,ChipMOS Technologies at Hsinchu Industrial Park, Chin Poon Industrial, King Cat Food, President Food, WeiZhuan Food, Far East Textile, Pingtung Ocean Museum, Taipei Ocean Museum, Ta Xi Resort, TianLai Spring Resort, Taipei Jen-ai Dibao of Hung Sheng Construction, National Taiwan University, National Chiao Tung University, National Chiayi University, Industrial Technology Research Institute, Nuclear Energy Research Institute, ZhongShan Institute of Science and Technology etc. |

|

| ¡@ |

| TOP |

|

|

|

|

|